Mi egy több generációs családi vállalkozás vagyunk

A cégünk 1985-ben alakult, egyszemélyes vállalkozásként, amely azóta is 100%-os magyar tulajdonban lévő cégcsoport. Telephelyünk Kőszárhegyen található.

Magyar vállalatként az ország meghatározó műanyagipari gyártó vállalatává váltunk. A vevői követelmények rendkívüli felkészültséget és fejlődést követelnek. Ezek teljesítése érdekében, a fröccsöntési technológia modern vívmányait is fel kell használnunk. Alapelvünk a vevői igények magas szintű kielégítése.

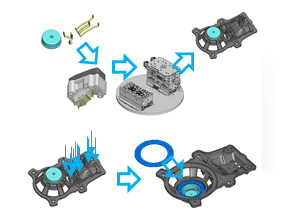

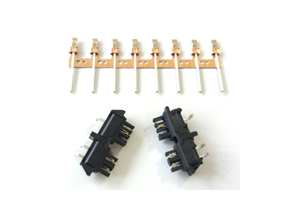

Több mint 75 db műanyag fröccsöntőgépünk mérettartománya 25 tonnától 1100 tonna záróerőig terjed. Az autóipari kábelkorbács csatlakozók mellett audio technikai alkatrészeket és esztétikai termékeket állítunk elő.